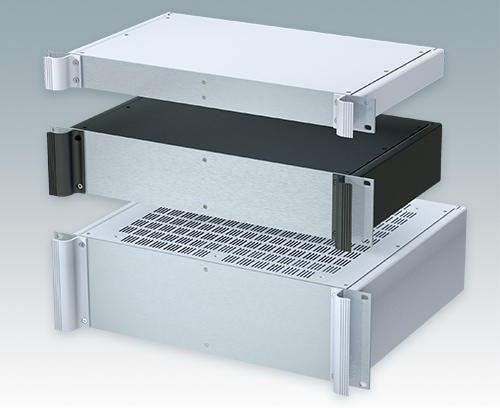

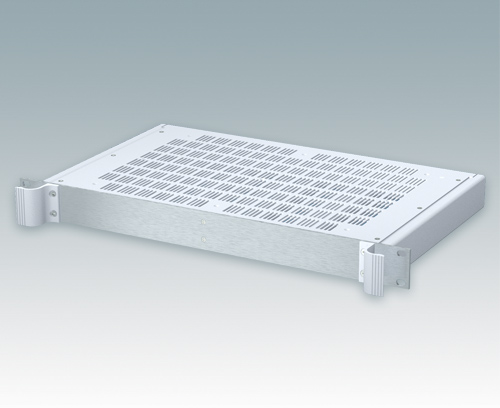

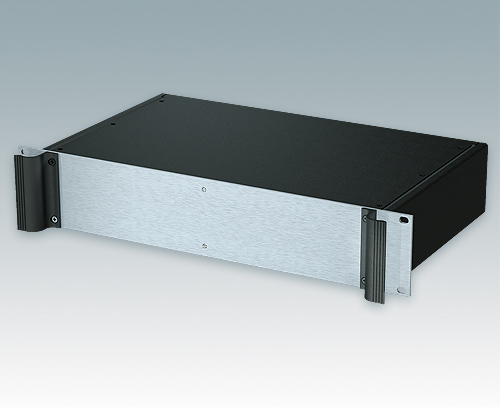

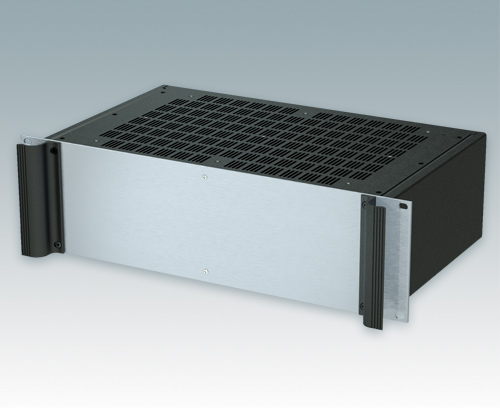

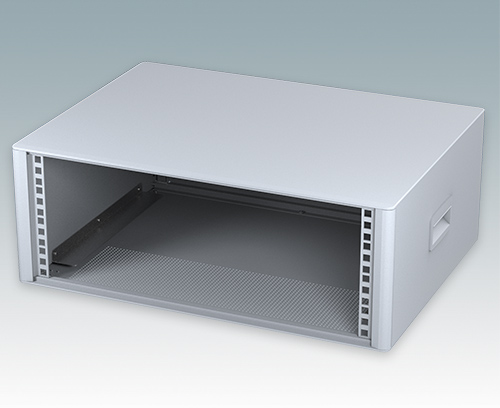

19" Enclosures

19" Enclosures

-

Enclosures

Enclosures Electronic enclosures | 19 inch rack mount enclosures

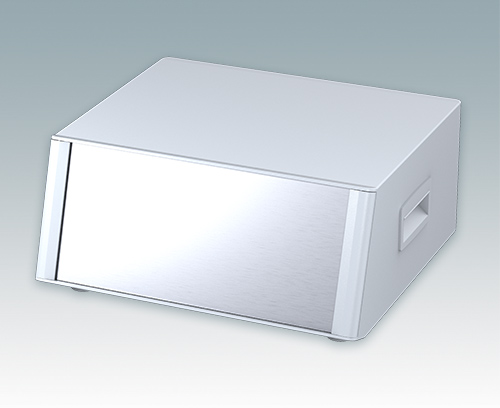

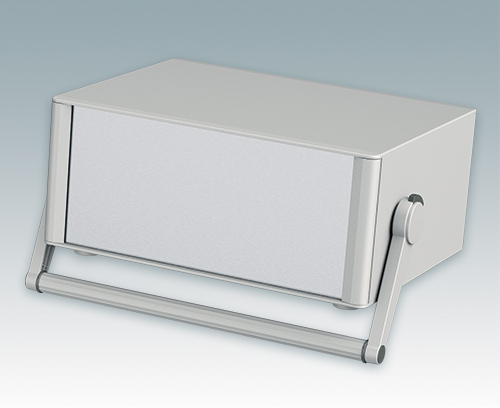

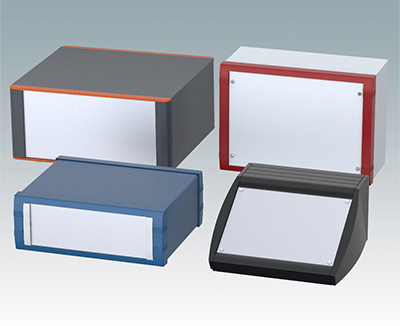

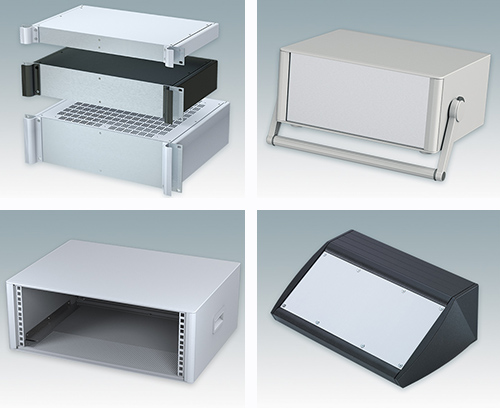

Versatile range including desktop enclosures; small instrument cases; portable enclosures with tilt and swivel carry handle bar; 19" rack mount enclosures and wall mount enclosures.

Metal Enclosures Modern metal enclosures for OEM electronics equipment

Metal Enclosures Modern metal enclosures for OEM electronics equipmentFor desktop, wall mount, portable and 19" rack mounted electronics equipment. All manufactured from high quality aluminium.

-

Accessories

Accessories Accessories for METCASE electronic enclosures and others

View the extensive range of accessories: 19" front panels, handles, enclosure feet kits, PCB guides and fixings.

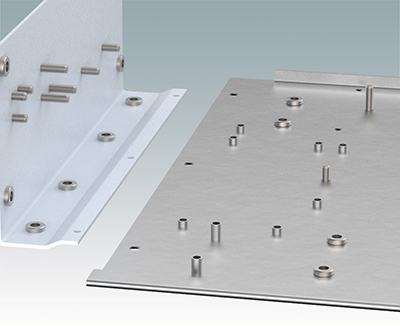

Accessories for Enclosures Extensive range of universal accessories

Accessories for Enclosures Extensive range of universal accessories19" front panels, enclosure feet kits, PCB guides and 19" mounting kits.

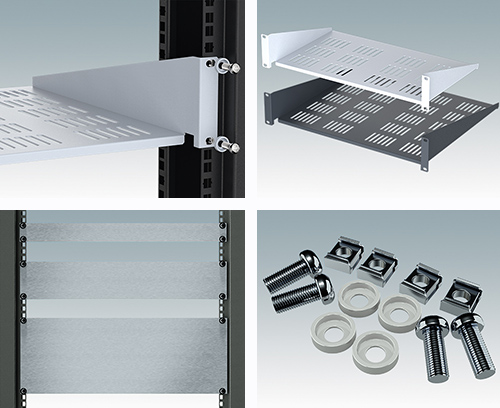

Accessories for 19" Racks Universal accessories for 19" equipment

Accessories for 19" Racks Universal accessories for 19" equipmentRange of universal 19" rack shelves, 19" front panels and fixings.

-

Custom Enclosures

Custom Enclosures Customised enclosures for OEM Electronics

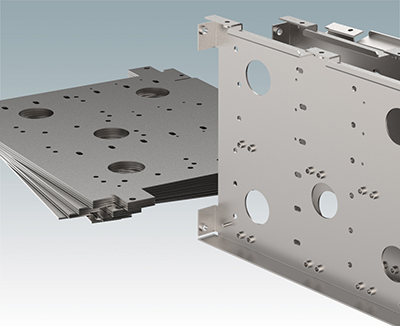

We can supply fully finished custom electronic enclosures with all the necessary modifications for mounting your PCBs, displays, connectors and other components.

Modifications & Finishing All the customising services you need

Modifications & Finishing All the customising services you needOur manufacturing site is equipped with all the equipment required to produce fully finished enclosures and front panels - ready for mounting your electronic components.

Bespoke Enclosures Bespoke metal enclosures and sheet metal parts

Bespoke Enclosures Bespoke metal enclosures and sheet metal partsFully bespoke electronic enclosures can be created using our standard case components such as diecastings and extrusion profiles or from fully fabricated sheet metal components.

-

News

News

Full details about all our new products and services along with company news.

News

News Press Releases

Press ReleasesRead our latest company press information and our complete press releases archive.

Blog

BlogOur blogs cover industry trends, how to's, customer applications, FAQs, international product standards and details about our new products and services.

-

About Us

About METCASE AustralasiaMETCASE is represented by ROLEC OKW Australia New Zealand Pty Ltd which is based in Penrith NSW.

Privacy Policy

Privacy PolicyROLEC OKW Australia New Zealand Pty Ltd is committed to protecting your privacy and has created this privacy statement in order to demonstrate our firm commitment to privacy.

-

Technical Info

Technical InformationHere can you download our datasheets, certificates, REACH, RoHS & WEEE statements, assembly instructions and catalogues.

Specifying Customised Enclosures

Specifying Customised EnclosuresSpecifying Customised Enclosures

REACH StatementWe are committed to meeting our legal obligations under REACH. Read our statement here.

ROHS / WEEE Directives

ROHS / WEEE DirectivesStatement regarding our product compliance with RoHS and WEEE directives.

Discontinued Products

Discontinued ProductsDiscontinued Products

-

Ordering

Ordering InformationFull information on placing an order, getting a quotation or sample, delivery charges, payment terms and typical delivery times.

-

Contact

Contact METCASEFull contact details including opening hours and meet our team. Plus how to make an enquiry or request a quotation and/or a sample.

General Enquiries Form

General Enquiries FormUse our contact form for general enquiries and requests for information, and to upload your documents and pictures.

Location Map

Location MapTravel information if you are visiting our sales representative ROLEC OKW in Penrith.

Worldwide Sales Network

Worldwide Sales NetworkWorldwide Sales Network